Tianda News

In the production process of chemical dyes, hot air system is essential. At present, most of the single-stage gASIfier is used to transport the mixed gas to the gas hot blast stove through pipe network, and the high temperature flue gas generated after combustion enters the spray tower to dry the raw materials. Because coal in the combustion process will produce NOX, SO and other harmful ingredients, especially SO on some key indicators of the product has a great impact, change heating process is urgent.

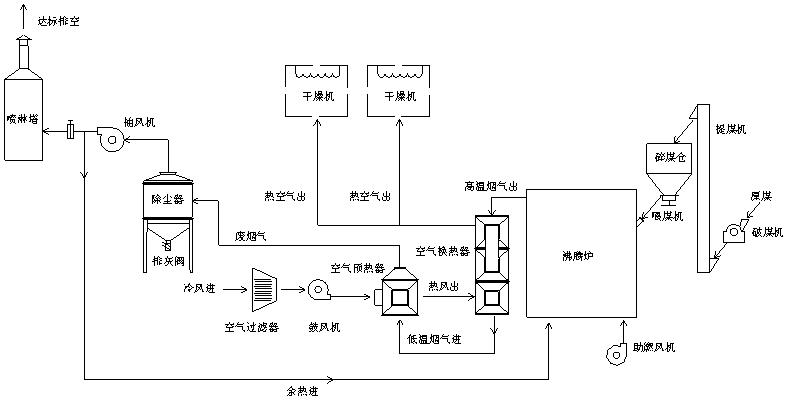

The hot air system for fine chemical dye drying is mainly composed of flue gas furnace, air heat exchanger and dust collecting system. The key technology of the system is that the hot air temperature of flue gas furnace should be stable and adjustable, the reaction time of temperature adjustment should be less than 5min, the local inferior coal with calorific value less than 4000kcal/kg can be burned, and the combustion efficiency should be greater than 95%. The required heat exchange efficiency of air heat exchanger should be greater than 75%, and it has the structure of high temperature erosion resistance and thermal expansion resistance. It is necessary to avoid the ash accumulation of hot flue gas caused by long-term use. Dust collection system needs to consider higher dust collection efficiency and lower operating cost to achieve standard discharge.

After the discussion and research of the project team, the system adopts the boiling furnace, tubular heat exchanger, multi-tube + water film dust removal process composition, the boiling furnace uses fluidized bed combustion technology, fuel adaptability is wide, can burn a variety of coal caloric value is lower than 3000kcal/kg, and the heating temperature is adjustable, the temperature is adjusted quickly, the burning rate is as high as 99%; The high temperature section of tubular heat exchanger is made of heat-resistant stainless steel, and the unique quinum-shaped jet tube structure is designed, which can effectively improve the heat exchange efficiency, reasonable bundle arrangement, and control the flue gas flow rate to be stable at 10m/s, which can avoid pipe ash accumulation. Dust removal system for dry method + wet method scheme, that is, waste flue gas first through the multi-pipe multi-dust collector, the dust collector is composed of a number of ceramic cyclone, dust removal efficiency can reach more than 95%, wind resistance is less than 900Pa, low operating cost; Then enter the water film dust removal tower, can further purify the waste gas, add desulfurizer, can desulfurize the flue gas.

By changing the heating process, the project achieved the direct drying of flue gas originally, and the harmful substances produced had an impact on the drying operation. Instead, it used hot flue gas to heat the air and then entered the drying operation, so as to avoid the hidden danger in production and improve the product quality. Moreover, the combined thermal efficiency of the system is more than 80%, the system is compact and feasible, the operation cost is low, and the service life of the equipment is more than 5 years, creating good economic benefits.